5 concrete slump|concrete slump vs strength : Brand What is a 5 inch slump of concrete? A 5-inch slump of concrete has medium consistency, represents a mix that is neither to stiff or too fluid, so it is easy to work and place in formwork.

webBlindspot is a thrilling TV show about a mysterious woman with tattoos that lead to a web of conspiracies. Find out where you can stream all seasons of Blindspot online with JustWatch, the ultimate guide for movie and TV streaming. Compare prices, platforms, and ratings for Blindspot and discover more shows you might like.

{plog:ftitle_list}

webEncontramos 9 Auto Escolas em Ouro Preto para você! Confira os telefones, endereços e horários de e-mails de contato de Auto Escolas mais perto de você. 9 resultados .

typical slump for concrete

vg30 compression test

Slump describes the water content and consistency of concrete and is measured by how much the mix slumps down when formed. Learn about concrete slump to ensure you have the right consistency for your concrete . A good slump for concrete is around 4 to 5 inches, similar in consistency to thick oatmeal, to ensure optimal strength and surface quality. Aim to avoid slumps greater than 5 inches to prevent weakening of the concrete.Concrete slump test is carried out from batch to batch to check the uniform quality of concrete during construction. The slump test is the most simple workability test for concrete, involves low cost and provides immediate results.Concrete slump is one of a suite of fresh concrete tests that include air content, unit weight, temperature, and the molding of laboratory samples for strength tests as specified in ASTM C94. These tests document the properties of the .

5 Significance of Slump in Concrete. 5.1 Relationship to Concrete Strength and Durability. 5.2 Presence of Segregated concrete. 5.3 Use in Determining Concrete Mix Proportions. Definition of the Slump in Concrete. Concrete .

What is a 5 inch slump of concrete? A 5-inch slump of concrete has medium consistency, represents a mix that is neither to stiff or too fluid, so it is easy to work and place in formwork. What is concrete slump? What tools do you need? What is the procedure to test concrete slump? Great questions. Let's break down the tools needed and the testing procedure step by step. The concrete slump test provides valuable information on the workability of concrete. In simple terms, it measures the consistency of concrete before it sets. A slump . The concrete slump test measures the workability of hydraulic cement concrete and verifies the consistency of various concrete loads in the field. It involves measuring the millimeters of subsidence of the specimen, .

A 5-inch slump in concrete indicates a medium consistency, making it relatively easy to work with and place in the formwork. How thick is concrete slump? The typical slump for ordinary decorative concrete .

5 Significance of Slump in Concrete. 5.1 Relationship to Concrete Strength and Durability; 5.2 Presence of Segregated concrete; 5.3 Use in Determining Concrete Mix Proportions; Definition of the Slump in Concrete. Concrete .The test is done by filling a cone with a sample of the concrete, removing the cone, and measuring how far the concrete has slumped. Concrete slump class. Concrete slump is labelled in terms of what class it falls into, ranging from S1 .A concrete slump test is a straightforward and essential procedure in the construction industry designed to evaluate the consistency and workability of fresh concrete. This test provides critical insights into the concrete’s fluidity, which directly impacts its strength and durability once it hardens. Understanding how to perform and .

normal slump value of concrete

The concrete slump class refers to the workability and consistency of a fresh concrete mix. This is measured by subjecting a fresh concrete batch with a slump test. The higher the slump of the concrete, the more fluid it is, . The concrete slump test is known as "Standard Test Method for Slump of Hydraulic-Cement Concrete" and carries the code (ASTM C 143) or (AASHTO T 119). United Kingdom & Europe. In the United Kingdom, the Standards specify a slump cone height of 300-mm, a bottom diameter of 200-mm and a top diameter of 100-mm. The British Standards do . The concrete slump cone is essential for conducting the concrete slump test, as it helps determine the correct water content and evaluate the flowability of the batch of concrete. Additionally, ensuring that the slump cone meets the required dimensions as per BS EN 12350-2 is crucial for obtaining accurate and consistent results with fresh . The slump test is applicable to concrete with medium to low workability, falling within the range of 5 to 260 mm. However, the test is not effective in assessing workability differences in stiff mixes with zero slump or in wet mixes resulting in a collapse slump.

To understand, why you need to check the quality of concrete, you must first understand what concrete is. Concrete is a composite material consisting of coarse aggregate which is stick together with fluid cement. Most of the times, the concrete used is lime-based and is termed as the Portland cement concrete.

The floor placement is running smoothly. Concrete slumps have ranged from 4 to 6 in.—the specification requirements—and the last truck is on site with about 12,000 cu. yd. of concrete on the . A good slump for concrete, if consolidated by vibration, should be 4 inches or less. When using other methods for consolidation, the slump for unsupported concrete should be 5 inches or less. What is the standard slump test concrete? The standard slump test for concrete requires pulling the cone straight up without twisting.

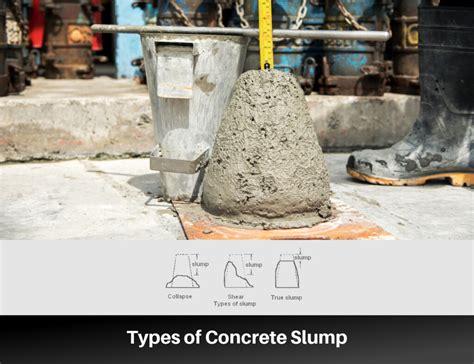

Sometimes, the concrete slump variations at site raises disputes between the parties involved in the construction process. Therefore, it is crucial to clarify the reason behind the need for concrete slump adjustment and the way it should be done in the field. If the concrete slump falls outside the specified range, the slump needs to be adjusted. All our brands of ready mixed concrete have already been slump tested. You can choose exactly what consistency of concrete you need by visiting our online ordering page.We offer five different types of concrete slump, ranging from dryer mixes (30 – 50 slump) and wetter mixes (90-120 slump).In this week's update, Deco-Jeff Hershberger shows you a concrete slump test!The term "slump" is commonly used in the industry to describe the consistency or.The slump is measured by how much the concrete settles from the height of the cone after it is removed. It is usually measured in millimeters or inches. Types of Slump. True Slump: The concrete maintains its shape and settles uniformly. Collapsed Slump: The concrete collapses completely, indicating it’s too wet. Shear Slump: The concrete .

How much strength do we forfeit for each additional inch of slump? The concrete in question has the following design criteria: 28-day compressive strength. 4,000 psi. Air content. 5 to 7 percent. Maximum size of coarse aggregate. 3/4 inch. Maximum water content. 298 pounds per cubic yard. Minimum cement content (Type II portland cement) 610 .And more importantly, the step-by-step procedure of slump test followed by the list of cautions during the test and way to measure the workability from the test result. Concrete Slump Test. The concrete slump test is an on-the-spot test .

Concrete slump test: workability slump concrete mix. Very low 0-25mm use dry mix concrete design. Low 25-50 low workability concrete mix design. Medium 50-100 medium workability concrete mix design. High 100-175 high workability concrete mix design . Factors affecting the concrete slump test: .5- Then the mold is lifted gently in the vertical direction and then unsupported concrete will slump. The decrease in height at the center point is measured to the nearest 5mm or 0.25 inch and it is known as ‘slump’. Cautions Required During Concrete Slump Test. 1- The inside of the mold and base should be moistened before every test. This guide will teach you how to perform the slump test on hydraulic cement concrete. It covers the reasons you are performing this test, the equipment needed, and the procedure of ASTM C143. It is intended to be a supplement to reading the ASTM as well as a study tool for the ACI exam.Be sure to read the dial while the thermometer is still inserted into the concrete. CONCRETE SLUMP TEST. Slump tests are applicable for concrete with slumps greater than 1/2 inch and less than 9 inches (read more about concrete slump). Once the concrete sample has been remixed, start taking the slump tests within 5 minutes.

In the world of concrete construction, ASTM C 143 is synonymous with ensuring workability. This standardized Slump Test measures the consistency of fresh concrete critical for both compliance and performance in building projects. Our article details the practical applications of the ASTM C143 Slump Test. It offers insights into interpreting key findings and highlights .sample of concrete show a falling away or shearing off of a portion of the concrete from the mass of the specimen, the concrete probably lacks the plasticity and cohesiveness necessary for the slump test to be applicable. 16. Discard the tested sample. Report • Results on forms approved by the agency • Slump to the nearest 5 mm (1/4 in.). A good slump for concrete is 4 to 5 inches, as this consistency is ideal for most exterior decorative applications. Avoid slumps greater than 5 inches to prevent a weak and porous surface. What does 80 slump mean in concrete? A slump of 80 indicates the concrete mix is highly fluid and workable. This makes it easier to pour and shape. What does 5 slump mean in concrete? The 4- to 5-inch slump for decorative concrete is a relatively stiff mixture, but not quite as stiff as the 2- to 3-inch slump seen here. A higher slumped concrete is more more fluid and will flow some distance on its own. What is S4 slump? S4 Very Wet (Foundations, slabs, Pumping and Piling concretes) 160-210.

Step1, Choice of Slump: If the slump for the mix is not specified, determine the appropriate maximum slump from the table below, the minimum slump of 1 in (25 mm) is already assumed. Recommended slumps for various types of construction Types of construction Maximum Slump in. (mm) Minimum Slump in. (mm) Reinforced foundation walls and footings Concrete slump testing is a procedure used to evaluate the workability and consistency of a concrete mix and the concrete slump test measures the concrete slump value with a slump cone. The required equipment for the concrete slump test, such as the tamping rod and slump cone, must adhere to applicable standards, such as ASTM C143 and AASHTO .

Recomendados para você. Descubra o clima para hoje e saiba o que esperar ao sair de casa. Previsão do tempo precisa para Boa Vista da Aparecida - PR hoje. Conheça já a Climatempo!

5 concrete slump|concrete slump vs strength